When it comes to wiring in marine environments, there's no room for compromise. Saltwater, moisture, UV exposure, and constant vibration pose serious threats to electrical connections. One of the most effective ways to safeguard your wiring at sea is by using waterproof heat shrink tubing—specifically designed for marine use.

In this guide, we’ll explore why it’s essential, how to choose the right type, and how to install it properly to ensure maximum protection.

1,Why Marine Wiring Needs Special Protection

Unlike household or automotive wiring, marine electrical systems are exposed to:

Saltwater corrosion: which degrades bare metal and connections rapidly

Humidity and moisture :leading to shorts and electrical failures

UV radiation :weakening standard tubing and causing cracks over time

Vibration and movement :especially on small boats and outboards

Failing to protect marine wiring properly can result in equipment malfunctions, safety hazards, or even fire risks.

2,What Makes Heat Shrink Tubing Waterproof

Not all heat shrink tubing is created equal. For marine applications, we recommend using marine grade electrical adhesive lined heat shrink tubing, another name is dual wall adhesive lined waterproof shrink wrap tubing.Here’s how it works:

Outer layer: Made of cross-linked polyolefin, it shrinks tightly around wires when heated

Inner layer: Meltable adhesive that flows and seals the connection completely

Together, they form a watertight, corrosion-resistant barrier, This makes it ideal for battery cables, bilge pump wiring, navigation lights, and sonar systems.

3,How to Choose Waterproof Heat Shrink Tubing for Boats and Marine Wiring

1) Material and Durability

• Polyolefin is the preferred material for marine heat shrink tubing due to its excellent resistance to saltwater, UV light, chemicals, and abrasion. It withstands extreme temperatures typically ranging from -50°C to 135°C (-60°F to 275°F), making it suitable for the marine environment1.

• The tubing should be cross-linked to enhance mechanical strength and chemical resistance.

2) Waterproofing and Adhesive Lining

• Choose dual wall heat shrink tubing with a heat-activated adhesive lining. This adhesive melts during heating to form a strong, waterproof seal around wires and connectors, preventing moisture infiltration and corrosion.

• The adhesive lining is crucial for creating an airtight and weather-tight seal that protects against water, oil, acids, salt, and sunlight exposure.

3) Shrink Ratio and Size

• Common shrink ratios are 3:1, and 4:1, indicating how much the tubing will shrink relative to its original size. A 3:1 ratio is common for marine use because it accommodates a wide range of wire sizes and provides a snug fit.

• Select tubing with a diameter that comfortably fits over the wire or connector before shrinking but shrinks tightly enough to seal after heating. For example, 1/4" tubing is suitable for 16 to 10 AWG wires, while larger wires like 2/0 AWG require 1" tubing.

4) Temperature Range and Flame Retardance

• The tubing should operate continuously in temperatures from about -55°C to 110°C or higher, depending on your specific environment.

• Flame retardant properties are important to reduce fire hazards on boats.

5) Additional Features

• UV resistance to prevent degradation from sunlight exposure.

• Chemical resistance to withstand exposure to oils, fuels, and acids common in marine environments.

• Strain relief to protect connections from vibration and mechanical stress.

• Color options and custom printing for wire identification and organization, which enhances safety and maintenance efficiency.

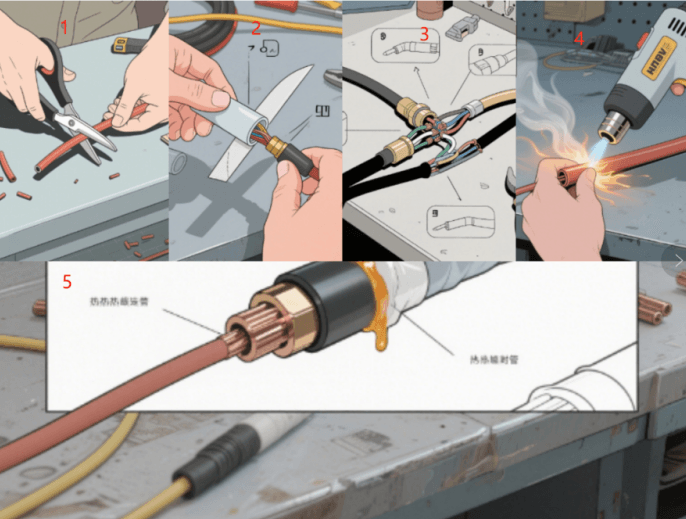

4, How to Use Heat Shrink Tubing For Marine Wiring

• Cut the tubing to the required length.

• Slide it over the wire or connector before making the connection.

• Use a heat gun to evenly apply heat until the tubing shrinks tightly and the adhesive melts, forming a waterproof seal.

• Allow to cool before handling to ensure the seal is fully set.

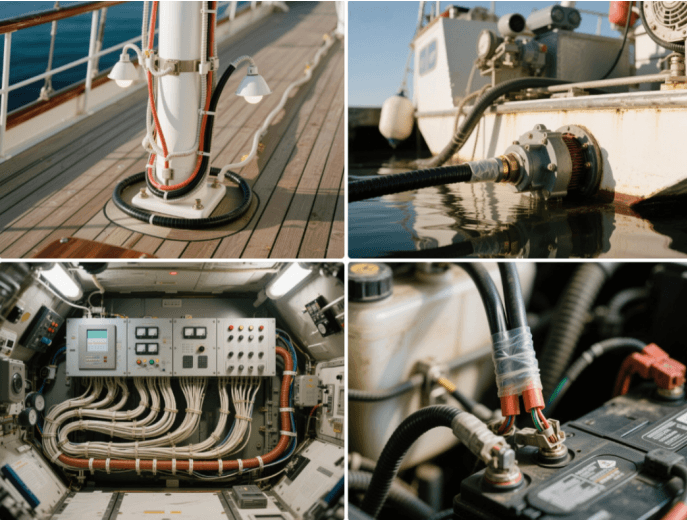

5, Recommended Applications in the Marine Field

• Outboard motor power cables

• Boat trailer wiring

• LED lighting on decks or cabins

• Bilge pump and float switch wiring

• Fishfinder/GPS installations

Whether you're a boat owner, marine electrician, or OEM in the marine industry, using waterproof heat shrink tubing is a small investment that can prevent big problems. It keeps your wiring safe, dry, and functional in the harshest environments.

6, Contact JS Tubing for High-Quality Heat Shrink Tubing & Wire Harness Accessories

Looking for reliable heat shrink tubing and wire harness accessories? JS Tubing offers premium-quality products backed by over 10 years of industry expertise.

As a trusted supplier of heat shrinkable tubing and flexible tubing, we proudly serve clients across the electrical, telecommunications, automotive, military, and aerospace industries.

Our products meet rigorous performance standards and are trusted by commercial and industrial customers worldwide.

✅ Competitive pricing

✅ Fast, responsive service

✅ Custom sizes & materials available

Get in touch with JS Tubing today to discuss your project needs or request a sample!